Decoding Wood Panels: Plywood, MDF, and Particle Board Compared

What is Particle Board?

Particle board is a type of engineered wood product that is made by compressing wood/bagasse chips and particles with a binder under high pressure and temperature. It is one of the most environment-friendly materials as it uses waste material effectively. As particle board is made from wood waste it is relatively inexpensive as compared to its alternatives such as MDF and Plywood. Particle Board is also called chipboard or low-density fibreboard (LDF).

Bagasse-based particle board is a type of engineered wood product that is made from bagasse, a fibrous residue left over after the extraction of juice from sugarcane. Bagasse is an agricultural waste material that is typically burned or discarded. However, it can be recycled and used as a raw material in the production of particle boards. To manufacture bagasse-based particle boards, the bagasse fibers are first dried and then mixed with a binder, such as urea-formaldehyde resin or other suitable adhesives. The mixture is then formed into panels under high pressure and temperature, using a process similar to the production of traditional particle boards.

Particle board is a popular building material used in almost every construction project. It is extensively used in the production of all types of furniture, flooring underlayment, countertops, panelling, and partition structures. Particle boards are gaining popularity due to its versatility, easy availability and less cost.

What is MDF?

MDF stands for Medium-Density Fiberboard, which is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. The resulting boards have a dense and uniform composition, with no knots or grain patterns, making them an ideal substitute for solid wood in a variety of applications.

MDF is widely used in furniture making, cabinetry, millwork, and construction, among other applications. It is particularly popular for its affordability, consistency, and ease of use. It can be easily cut, shaped, and routed using standard woodworking tools, and its uniform composition makes it easy to paint, veneer, or laminate.

One of the major advantages of MDF is its consistency in thickness, density, and strength. This makes it ideal for applications where dimensional stability and strength are critical, such as flooring, shelving, and structural panels. MDF is also an eco-friendly alternative to solid wood as it is made from recycled wood fibers and does not contribute to deforestation.

Overall, MDF is a versatile and cost-effective material that has found wide applications in various industries.

What is Plywood?

Plywood is a type of engineered wood product made by gluing together several thin layers of wood veneers or plies, with the grains of adjacent layers rotated perpendicular to each other. This cross-graining technique gives plywood its strength and stability, making it a versatile and widely used material in the construction and furniture industries.

Plywood can be made from a variety of wood species, including hardwoods, softwoods, and tropical hardwoods. It is available in a range of thicknesses, sizes, and grades, with different grades indicating the quality and appearance of the plywood.

Plywood can be used in a variety of applications, such as furniture making, flooring, wall paneling, roofing, and sheathing. It is particularly popular for its strength, dimensional stability, and durability. Plywood is also a sustainable and eco-friendly material, as it is made from renewable resources and can be recycled or repurposed at the end of its life.

Overall, plywood is a highly versatile and cost-effective material that has found wide applications in various industries. Its strength, stability, and durability make it a popular choice for construction and furniture making, while its sustainability makes it an eco-friendly alternative to solid wood.

When comparing plywood, MDF (Medium-Density Fiberboard), and particle board, it’s important to consider factors such as composition, strength, durability, cost, and application suitability. Here’s a comparison of these three common engineered wood products:

Plywood v.s. MDF v.s. Particle Board

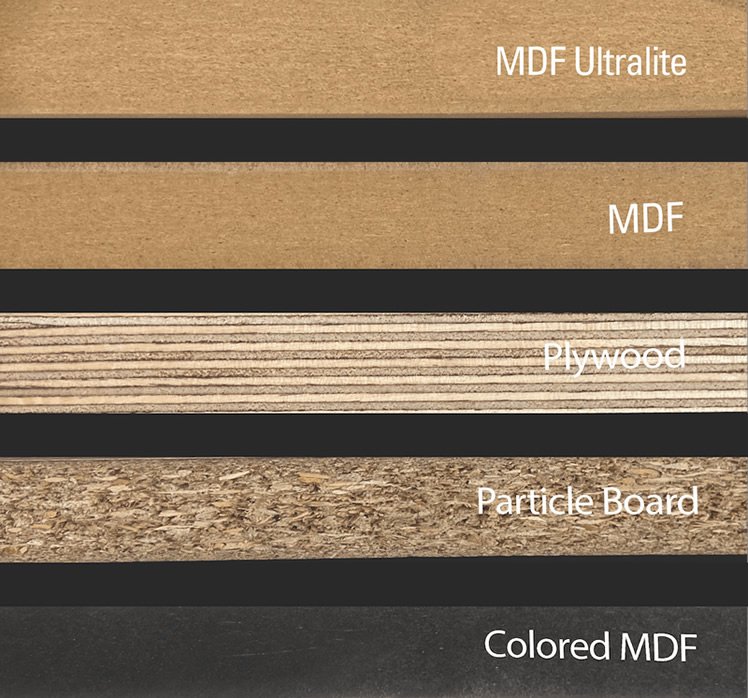

1. Composition:

- Plywood: Plywood is made from thin layers of wood veneer glued together with alternating grain directions. This construction provides strength and stability.

- MDF: MDF is composed of fine wood fibers combined with a binder and compressed under heat and pressure. It has a uniform composition throughout.

- Particle Board: Particle board is manufactured by compressing wood particles or chips with a resin binder. It has a coarse texture due to the larger wood particles.

2. Strength and Durability:

- Plywood: Plywood is known for its high strength and durability. It is resistant to warping, twisting, and splitting. The number of layers and the quality of the veneer impact its strength.

- MDF: MDF is not as strong as plywood, but it is stronger than particle board. However, it is more susceptible to moisture damage and can swell or break if exposed to excessive water.

- Particle Board: Particle board is the least strong and durable among the three. It can be prone to swelling and damage if exposed to moisture. It is not suitable for applications that require high strength or load-bearing capacity.

3. Surface Finish:

- Plywood: Plywood typically has a natural wood grain surface, which can be left exposed or covered with a veneer, laminate, or paint. The quality of the surface appearance depends on the grade and quality of the plywood.

- MDF: MDF has a smooth and uniform surface, making it ideal for applications where a painted or laminated finish is desired. It does not have a natural wood grain pattern.

- Particle Board: Particle board has a rough and coarse surface due to the larger wood particles. It is often used as a substrate material where the surface will be covered with veneer, laminate, or other finishing materials.

4. Cost:

- Plywood: Plywood is generally more expensive than MDF and particle board due to its manufacturing process and higher strength.

- MDF: MDF is usually more affordable than plywood and can be a cost-effective option for furniture and cabinetry.

- Particle Board: Particle board is the least expensive among the three engineered wood products, making it a budget-friendly choice for various applications.

5. Applications:

- Plywood: Plywood is commonly used in construction, furniture, cabinetry, flooring, and applications that require high strength, durability, and stability.

- MDF: MDF is often used in furniture, cabinetry, interior millwork, shelving, and decorative applications that require a smooth and uniform surface finish.

- Particle Board: Particle board is commonly used for furniture, shelving, cabinets, and interior applications where cost-effectiveness and surface smoothness are prioritized.